- Home

- / rapid prototyping

Rapid Prototyping

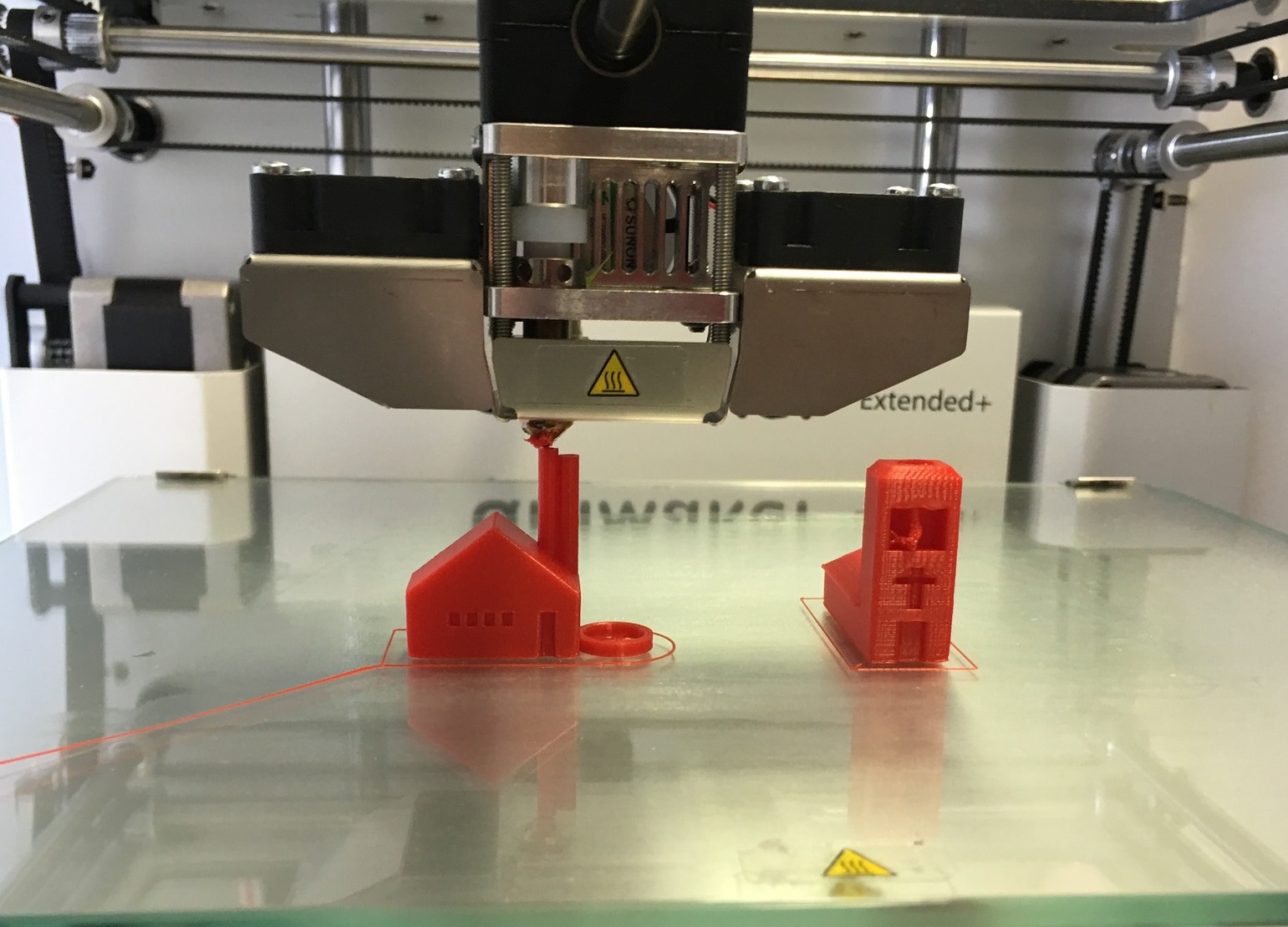

Product development challenges are myriad, and shortening time to market is the number one strategic goal of innovator/entrepreneur and organizations. One such challenge is post proof concept stage (POC) work. Brining out a fully functional product for validation, risk mitigation, and addressing scale-up concerns requires a fully functioning ecosystem of infrastructure, workforce, parts vendors, and mentors.

A Rapid Prototyping Centre (RPT) is a go-to place for all such requirements to help convert a POC into a functional product. An RPT may need to integrate few critical facilities under a single roof to save time, cost, and effort to ensure the required flexibility to do, undo and redo WHATEVER required to achieve goals.

Quicker To Innovate Faster To Validate

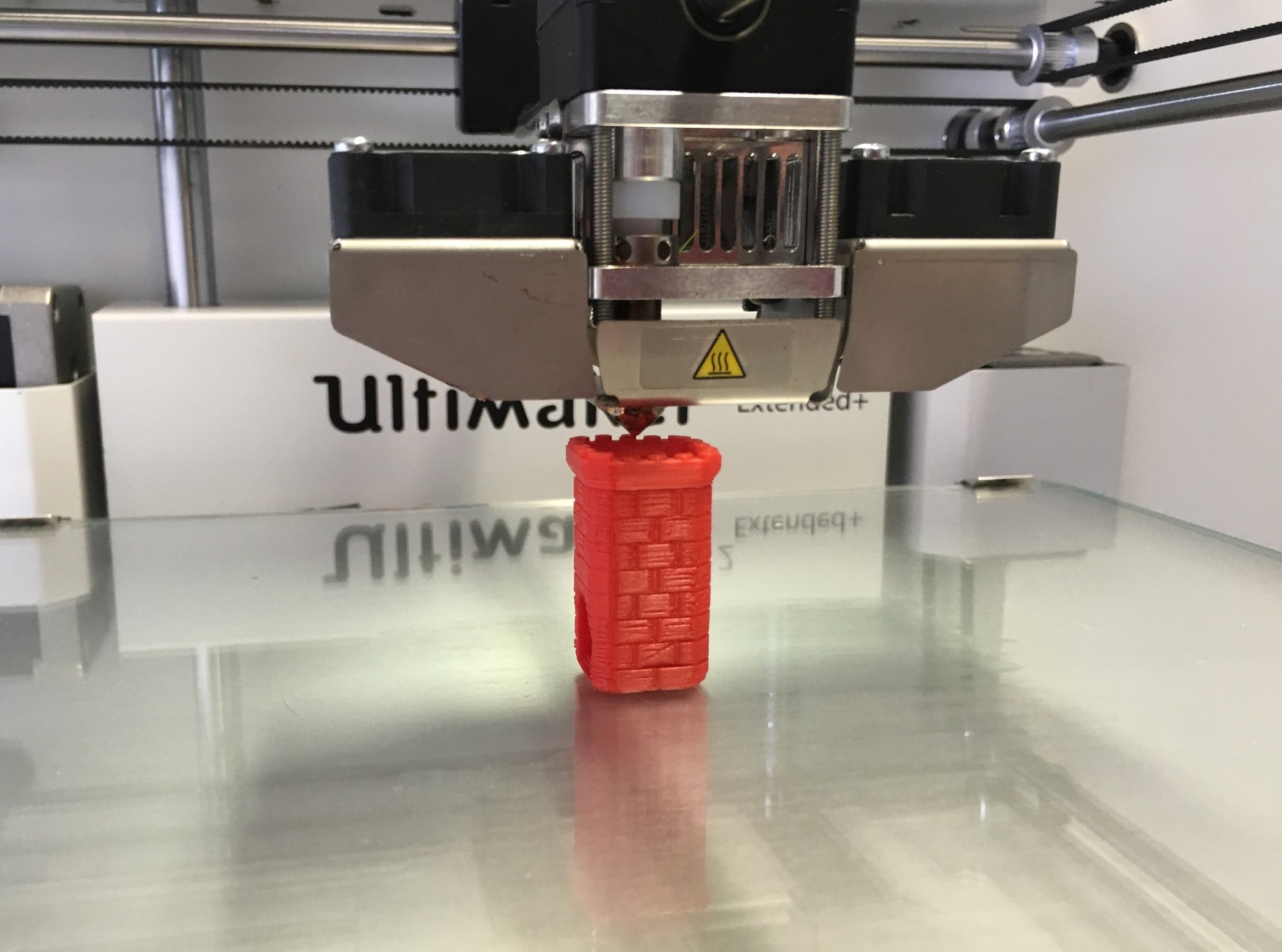

Conceptualizing many design options needs a faster validation mechanism, so that after feedback is received, designs can be refined and this iterative process continues till the design meets the required performance criteria.

Reduce Non-productive Investment

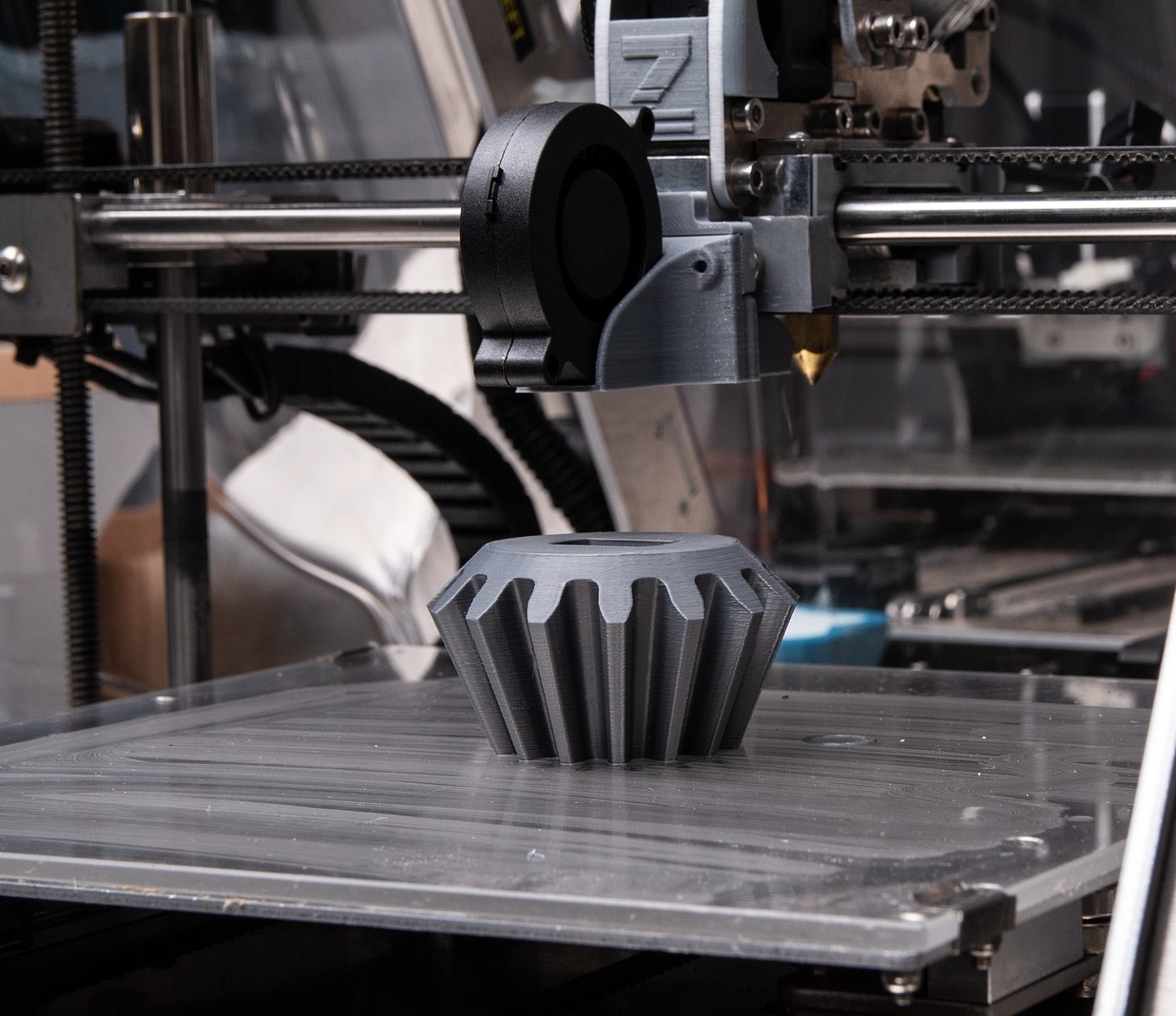

Since 3D printing does not require dies, jigs, fixtures, the entire development cycle can be accomplished with reduced expenditure in a shorter period. Before committing considerable resources in full-scale manufacturing, an entrepreneur can cut losses by withdrawing potentially failure products.

Reduce Time-to-market

Design and performance challenges can be identified at an early stage, and products can be modified or redesigned if required in a much shorter period. RPT also facilitates small scale manufacturing, allowing tasks like test marketing, customer validation, and regulatory compliance. Entrepreneurs can learn what may potentially work in the market place and change plans accordingly.

Benefits

following are the benefits for the Rapid Prototyping

- Reduced design & development time.

- Advances “time to market” turn-around.

- Reduces waste with additive manufacturing.

- Improve lives, one customized part at one time for medical application.

- Saves weight with complex part designs.

- Elimination or reduction of risk.

- Allows functionality testing at a fraction of the cost.

- Ability to evaluate human factors and ergonomics.