- Home

- / resources

- / Metal & Non-Metal Machines

Metal & Non-Metal Machines

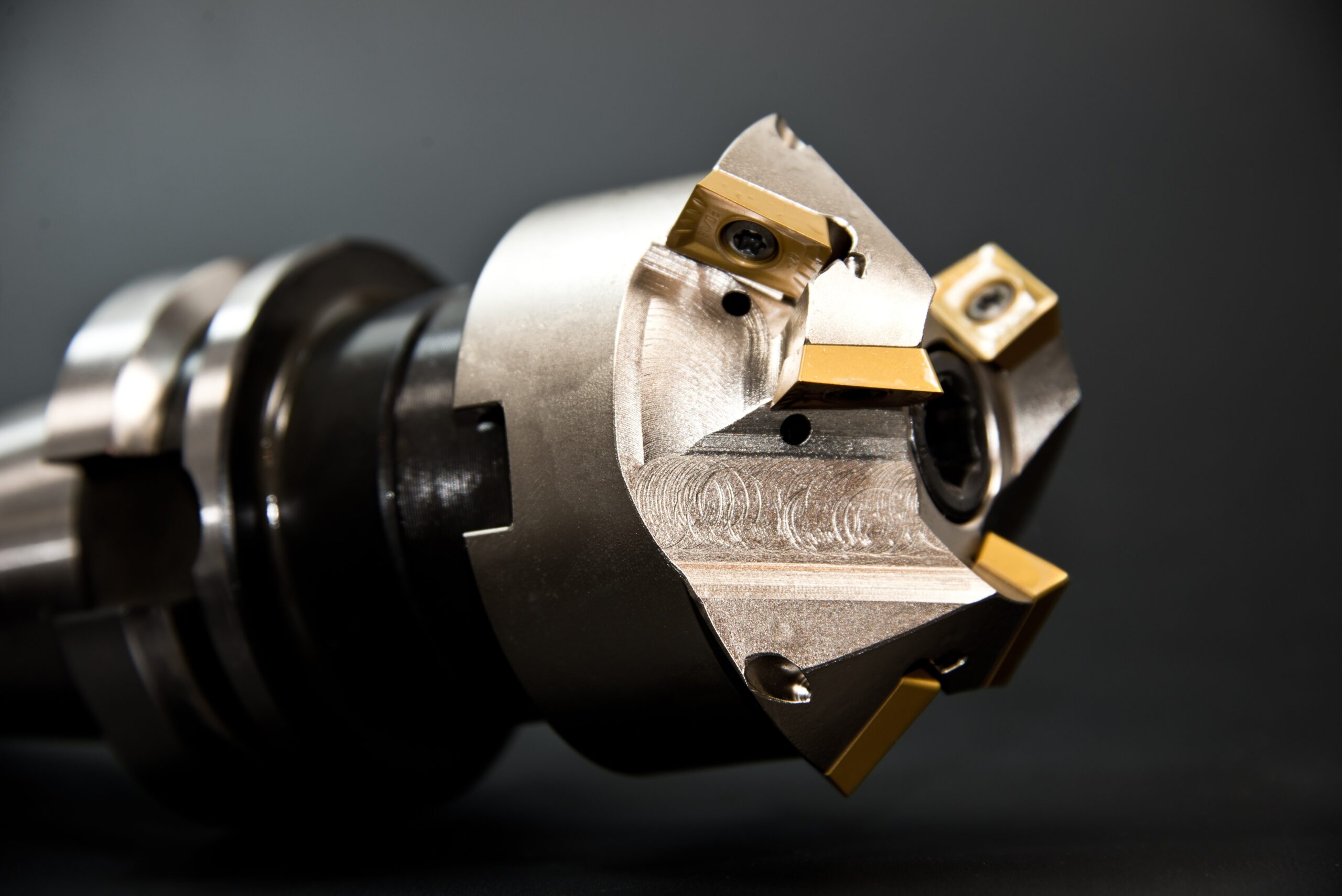

CNC Machining Facility is very important manufacturing process for Medical Industry. Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, in contrast to additive manufacturing, which uses controlled addition of material. We are equipped with versatile machining facility with latest CNC Controllers, spindle power to handle a range of jobs, and tool changing mechanism for faster prototyping.

Marathwada MedTech Lab is equipped with versatile machining facility with latest CNC Controllers, spindle power to handle a range of jobs, and tool changing mechanism for faster prototyping.

- 4th and 5th axis to work on complex geometries

- Precision machining to tight tolerances

- Ultra-high level of cleanliness

- A wide material selection that includes stainless steel and medical-grade plastics such as PEEK

- High-level surface finishing capabilities

- Common Materials for Machined Parts

- Cobalt-chrome alloys

- Stainless steels (for temporary implants)

- Polyether ether ketone (PEEK)

CNC Turning Centre Features:

- Cartridge type spindle supported with precision angular contact ball bearing

- LM guides and pre-loaded ball-screws for both the axis

- 3-Jaw self-centering chuck

- Hollow rotary cylinder

- 8-station bi-directional Hydraulic turret

- Tail stock with programmable quill

- Coolant tank with chip tray

- Hydraulic power-pack

| Specifications | |

|---|---|

| Capacity | |

| Max. Swing Over Bed | 550 mm |

| Max. Turning diameter | 350 mm |

| Max. Turning Length | 705 mm |

| Swing over carriage | 330 mm |

| Admit between centre | 800 mm |

| Spindle | |

| Max. Speed | 3500 RPM |

| Spindle Nose | A2-8 |

| Spindle motor | 11.0/15 KW/HP |

| Chuck | 250 mm |

| Turrent | |

| No. Of Station | 8 |

| Model : HTP100 | HTP100 |

| Max. Boring Bar dia | 40 mm |

| OD turning tool size | 25X25 mm |

| Tail Stock | |

| Quill diameter | 80 mm |

| Quill base travel | 600 mm |

| Quill travel | 100 mm |

| Quill taper | MT-4 |

| Controller | Fanuc Oi TF |

VMC Machine

Vertical Machining Center with 4th and 5th Axis for machining complex geometries

VMC Centre Features:

- AC servo drives

- AC variable speed spindle motor

- LM roller Guide-ways

- Hardened & ground ball screws

- Feedback through absolute encoder

- Automatic tool clamping-unclamping

- Centralised automatic lubrication

- Spindle taper air blow

- Front chip disposal

- Electronic Counterbalance for std configuration

| Specifications | |

|---|---|

| Table | |

| Table Size | 1300×600 |

| T-slot Dimention | 5/18/100 |

| Distance from Floor to Table | 1000 |

| Max Load on Table | 1100 |

| Capacity | |

| X-Axis Travel | 1100 |

| Y-Axis Travel | 600 |

| Z-Axis Travel | 600 |

| Dis. From Spindle Face to Table Top (Min.-Max.) | 150-750 |

| Feed | |

| Rapid Traverse (X,Y & Z Axis) | 32/32/32 |

| Cutting Feed | 1-10000 |

| Main Spindle | |

| Spindle Speed Range | 6000 |

| Spindle Motor Power -Fanuc | 11/7.5 |

| Spindle Nose | BT – 40 |

| 4th and 5th Axis | UCAm make tilting table dia of 200 mm |

| Die and Mould Kit | AICC with 200 look ahead |

| Automatic Tool Changer | |

| Accuracy (As per VDI/DGQ 3441) | |

| Positioning Uncertainty (P) | 0.016 |

| Repeatability (Ps medium) | 0.012 |

| Control System | Fanuc Oi MF |

Laser cutting Machine

The laser cutting machine is available for nonmetal materials.

| Table | |

| Working Area | 1220 mm x 1200 mm |

| Laser Power | 130 Watt (Peak Power 150 Watt) |

| Wavelength | 10.6 micrometer |

| Reposition Accuracy | ± 0.05mm |

| Graphic File Support | PLT, CDR, AI, DWG, DXF, DST, BMP, JPEG, TIFF, GIF, PCX |

Rate card

| Sr. No. | Service | Rate |

| 1. | VMC | 350 Rs per Hour |

| 2. | CNC Lathe | 250 Rs per Hour |

| 3. | 3D scanning | 1300 Rs per Hour |

| 4. | 3D printing | Depends on material print volume and post processing time |

| 5. | Laser cutting | 10 Rs per minute |

| 6. | PCB prototyping | Depends on pcb design |

Looking for a solutions for your home or business?